Turnkey works for the Skalisty mine

- Client: Thyssen Shakhtbau GMBH, operating through its representative office in Norilsk

- Task: ACRUS® fire-proof and anticorrosion coatings application at the Skalisty mine site.

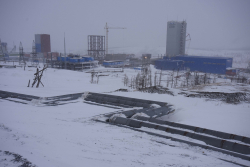

PJSC MMC Norilsk Nickel, a Russian company, stands as a global leader in the mining and metallurgical industry, both in Russia and internationally. Among its assets is the Skalisty Mine, which holds the distinction of being the deepest mine not only within Norilsk Nickel but also across Eurasia, with depths exceeding two kilometers.

The Skalisty Mine serves as a vital source for replenishing the depleting capacities of the Polar Branch with high-grade ore.

German company THYSSEN Schachtbau secured contracts to construct two of the deepest mine shafts in Eurasia—SCS-1 and VS-10—employing innovative methods previously unseen in Russia. Currently, the depth of skip-cage shaft No. 1 reaches 1,890 meters.

The sinking operations are facilitated by sinking machines provided by OLKO Maschinentechnik GmbH. These machines are expected to reach the deep deposits of the Oktyabrsky ore field by 2022. Skalisty boasts three shafts that form the backbone of production, with mining activities occurring at depths ranging from 700 to 900 meters.

Ongoing efforts at BC-10 focus on re-equipping the shaft for continuous operation. Surface production buildings are currently undergoing work. Under the supervision of chief engineers from SIEMAG and ELPRO, installation of cage and skip lifting machinery is completed, while electrical work on the skip lifting equipment remains in progress.

AKRUS® successfully executed a comprehensive turnkey project for restoring anticorrosive protection and applying fireproof coatings to the metal structures of the cage and skip hoists, as well as the surface facilities at the SCS-1 shaft of the Skalisty Mine.

The project was carried out exclusively with AKRUS® products.

To achieve the R150 fire protection standard, AKRUS® FM (foil-coated basalt mats) was utilized. For protecting galvanized surfaces, AKRUS® Epoxy S (AL) was applied, along with the AKRUS® Epoxy S anticorrosion protection system.