The company AKRUS® is: development and production of anticorrosive, flame—retardant, heat-resistant, waterproofing coatings of the AKRUS® brand for protective purposes, used in such areas as civil and infrastructure construction, road construction, shipbuilding and ship repair, bridge construction. "The company has been on the market for more than 17 years."

Execution of specialized contract works on the application of protective paint coatings and the device of anticorrosive protection, fire protection, thermal insulation in protective construction.

- 3

- 5

- 6

- 8

- 0

- 4

- 6

- 6

Our company owns its own production base, contracting facilities and a a complex of specialised equipment. The technical and production potential of our company allows us to be bold and decisive in our development, set new goals and specialised equipment. allows us to be bold and decisive in our development, set new goals and realise them. realise them. Over the years of work AKRUS® anticorrosion coatings have protected more than 26,000,000 m2

We provide stable quality and long-lasting protection during many years of operation of objects in real protective conditions. We provide consistent quality and long-lasting protection over many years of operation under real protective conditions.

Highly qualified personnel with the necessary on-site experience

Knowledge of international standards, successful experience of work on foreign and Russian objects ensures a high level of work quality, compliance with deadlines and fulfilment of obligations. commitments.

The AKRUS® materials production facility is designed by a leading engineering company. It is equipped with modern European technological equipment. The production capacity is 9000 tonnes per year.

High-tech equipment allows AKRUS® brand to compete with the world leaders in the production of anticorrosion coatings.

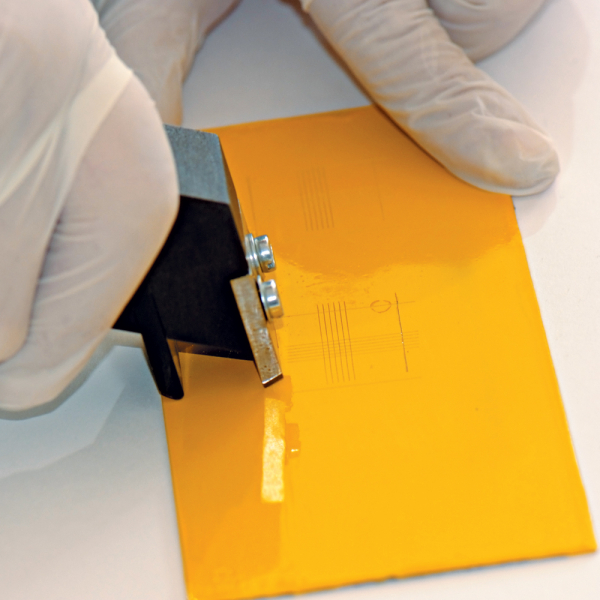

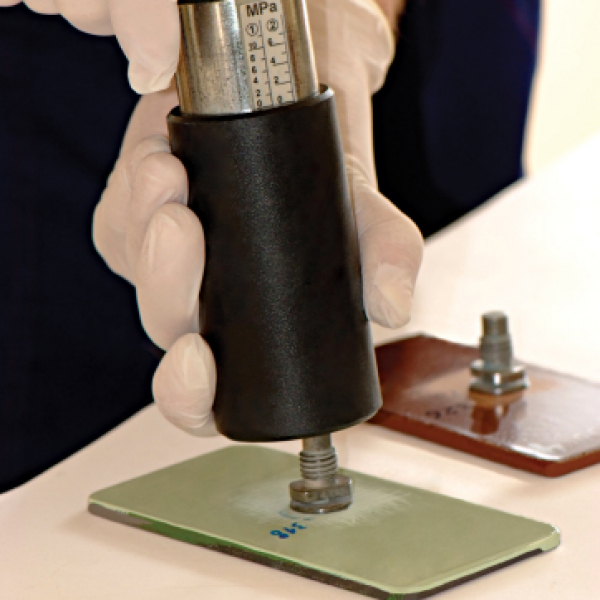

AKRUS® brand products undergo quality control at all stages of production, which includes incoming quality control of raw materials, operational control at all stages of production and acceptance tests of finished products. The use of raw materials from world-known chemical concerns also guarantees the quality and stability of product properties.

The coatings of AKRUS® brand are successfully used at large infrastructure facilities of such companies as Gazprom, Lukoil, Transneft, Tatneft, Rosneft, OSK, Rosmorport, SSC Zvezda and others.

The advantages of AKRUS® materials are confirmed by such strategic programmes as "Modernisation of the transport system of Russia", "Development of the chemical and petrochemical industry of the Russian Federation until 2015", "Construction of the oil pipeline system "Eastern Siberia Pacific Ocean".

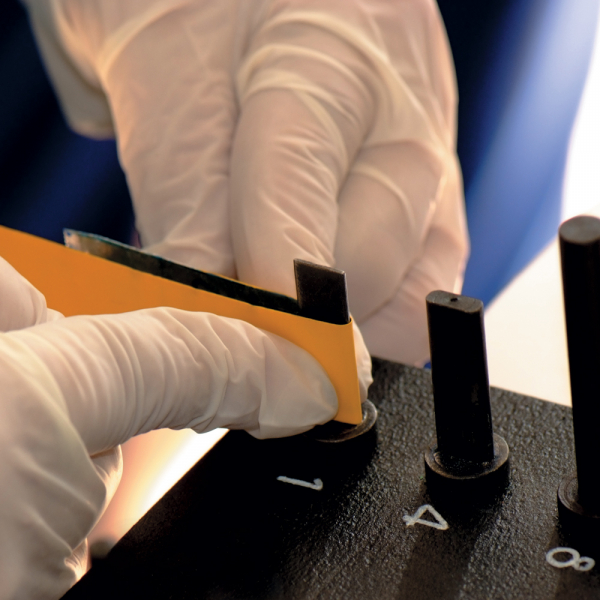

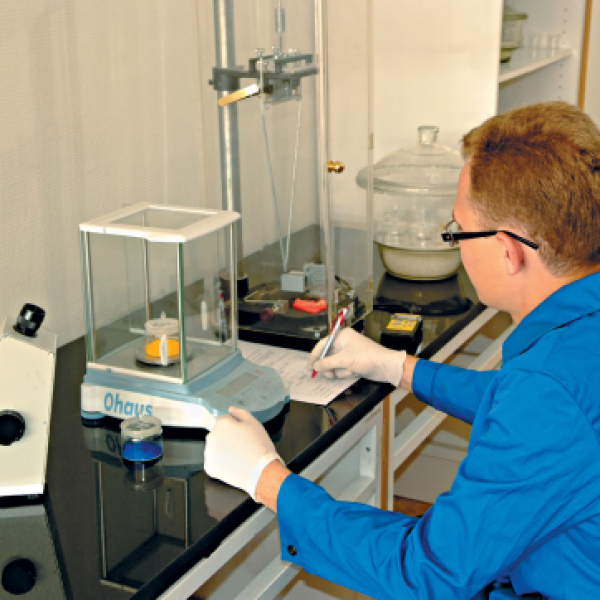

In our own scientific laboratory, the specialists of the company ACRUS ® carry out analyses and tests of paintwork components at all stages of the creation of materials, every day they work on improving technical indicators and characteristics. Here we develop the most innovative products— high-tech, eco-friendly and solutions that meet the increasing demands of consumers.

The specialists of the innovation laboratory are developing new types of anticorrosive and flame-retardant coatings for use in particularly extreme physical and atmospheric conditions:

- extremely low temperatures;

- permafrost zone;

- aggressive environments;

- climate contrast.

AKRUS® warehouses are a fine-tuned, multi-level system, integrated into a large technological process with systems for the accounting of stored materials, starting with the receipt of raw materials, transferring them to production, storing finished products, and ending with order picking and release to the end customer.

Our warehouses are a complex structure consisting of technical and managerial sides. And various innovations and scientific progress are changing the structure of warehouses, turning them into a complex of automated storage and distribution management systems.

Our partners

Long service life

ISO, ASTM and GOST RF technologies

Operation in sub-zero temperatures

High professionalism

Significant cost savings

Designing

AKRUS® is a member of the Association of Steel Construction Development that unites all the industry participants. Industrial fireproofing and corrosion-resistant coating materials developed and produced by AKRUS® are used for steel constructions coating in civil, infrastructure and road construction, as well as in ship building and repair, and bridge construction.

Our company was among the enterprises of Moscow, on which the national project “Labor Productivity and Employment Products” has launched, the purpose of which is to increase labor productivity through the use of lean production tools, as well as advanced training and personnel involvement. The project operator is the Federal Competence Center (FCC).